Waste wood processing for recycling

GOOD JOB.

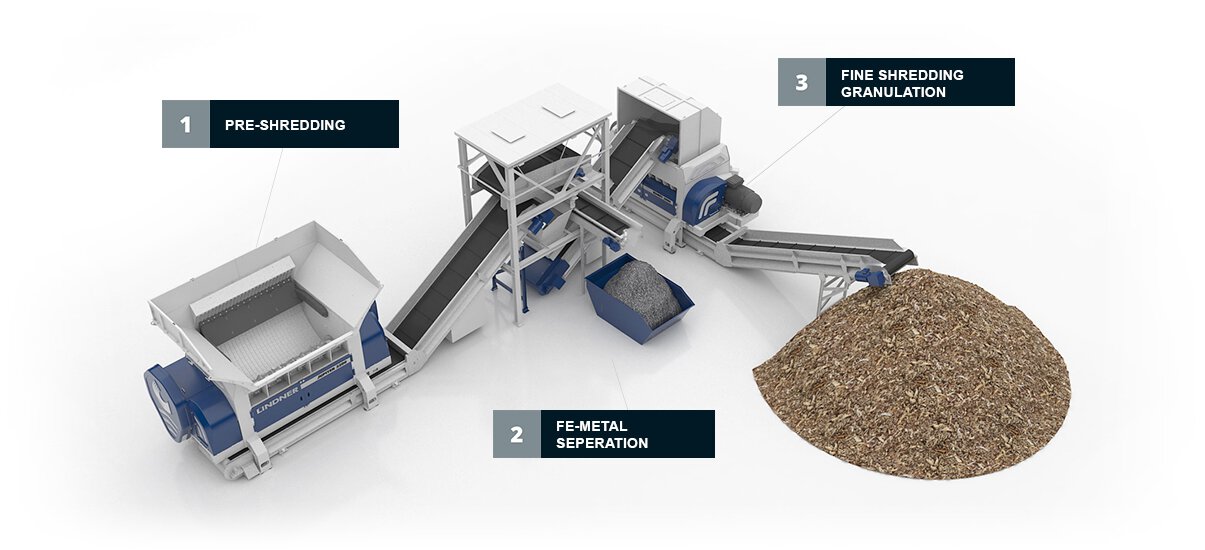

Excellence in shredding: Lindner’s multi-stage processing solution leaves nothing to be desired. Powerful primary shredders combined with well-engineered separation technology and high-precision Komet secondary shredders ensure not only the perfect output, but also the necessary throughput to keep downstream processes running.

SHREDDER REQUIREMENTS

The primary shredder’s task is to coarsely shred the material. Especially in the case of bulky wooden panels or large pallets, it must be able to pull in material effectively and autonomously. The large point-to-point square cutters of the JUPITER series run slowly, go easy on the material, are resistant to foreign matter and extremely efficient.

Related Product

shredder requirements

As a secondary shredder or granulator, a high-speed rotor shredding system is usually used in the final stage due to the material already being ‘clean’. Our high-speed KOMET series with its shear cutters and always precise cut facilitates the highest output rates and constantly high-quality waste wood output.

Related Product

Anforderung an den Shredder

Der Zerkleinerer muss dafür besonders robust und störstoffresistent ausgeführt sein, um die hohe Bandbreite an Inputmaterialien zu meistern. Das Ziel der Zerkleinerung ist eine wirtschaftliche Aufbereitung mit geringsten €/t-Kosten für den Betreiber mit einem stets konstanten Austrag von 50-100mm, fix und fertig verwendbar zur Befeuerung im Zementofen Kalzinator oder als Wirbelschicht- Brennstoff. Der POLARIS als die Kompaktlösung erfüllt die Anforderungen am besten.

Related Product

Anforderung an den Shredder

Der Zerkleinerer muss dafür besonders robust und störstoffresistent ausgeführt sein, um die hohe Bandbreite an Inputmaterialien zu meistern. Das Ziel der Zerkleinerung ist eine wirtschaftliche Aufbereitung mit geringsten €/t-Kosten für den Betreiber mit einem stets konstanten Austrag von 50-100mm, fix und fertig verwendbar zur Befeuerung im Zementofen Kalzinator oder als Wirbelschicht- Brennstoff. Der POLARIS als die Kompaktlösung erfüllt die Anforderungen am besten.

Related Product

Anforderung an den Shredder

Der Zerkleinerer muss dafür besonders robust und störstoffresistent ausgeführt sein, um die hohe Bandbreite an Inputmaterialien zu meistern. Das Ziel der Zerkleinerung ist eine wirtschaftliche Aufbereitung mit geringsten €/t-Kosten für den Betreiber mit einem stets konstanten Austrag von 50-100mm, fix und fertig verwendbar zur Befeuerung im Zementofen Kalzinator oder als Wirbelschicht- Brennstoff. Der POLARIS als die Kompaktlösung erfüllt die Anforderungen am besten.

Related Product

Primary shredding

After the wood has been sorted in accordance with the waste wood grades, A1 and A2 waste wood is processed in the first shredder. This slow-speed shredding system shreds pallets, chipboard, demolition and other partially bulky wooden parts with the aim of creating homogenous, well-broken-down material to subsequently separate nails and other metal parts from the material.

MAGNETIC SEPARATION OF FERROUS METALS

In the second step, a permanent magnet fitted above the conveyor belt is used to safely extract ferromagnetic parts such as nails, scrap iron and other scrap metals.

Secondary (Fine) Shredding | Granulation

The pre-shredded waste wood that is free from foreign particles and metals then enters the second shredding stage. The final product should be homogenous and about 15–30 mm in size to ensure that the recycled material is of high quality throughout for the production of chipboard later on.

WASTE WOOD PROCESSING FOR RECYCLING PURPOSES

Waste wood shredding for recycling in the circular economy

Recycling renewable resources such as wood plays an important part in environmental protection. Wood is often used for pallets, chipboard and demolition wood, etc. At the end of its life large quantities of it end up as waste wood on recycling companies‘ premises. Then particularly clean waste wood can be recycled and reused as a new product (e.g. recycled chipboard).

Particularly when recycling waste wood, it must be processed in several stages – mostly including these steps:

- Receipt, weighing and quality control

- Sorting in accordance with the waste wood grades (A1 - A4)

- Primary shredding

- Separating of recyclable material (e.g. metals)

- Secondary (fine) shredding/granulating