Mercilessly efficient:

Powerful performance, no compromises.

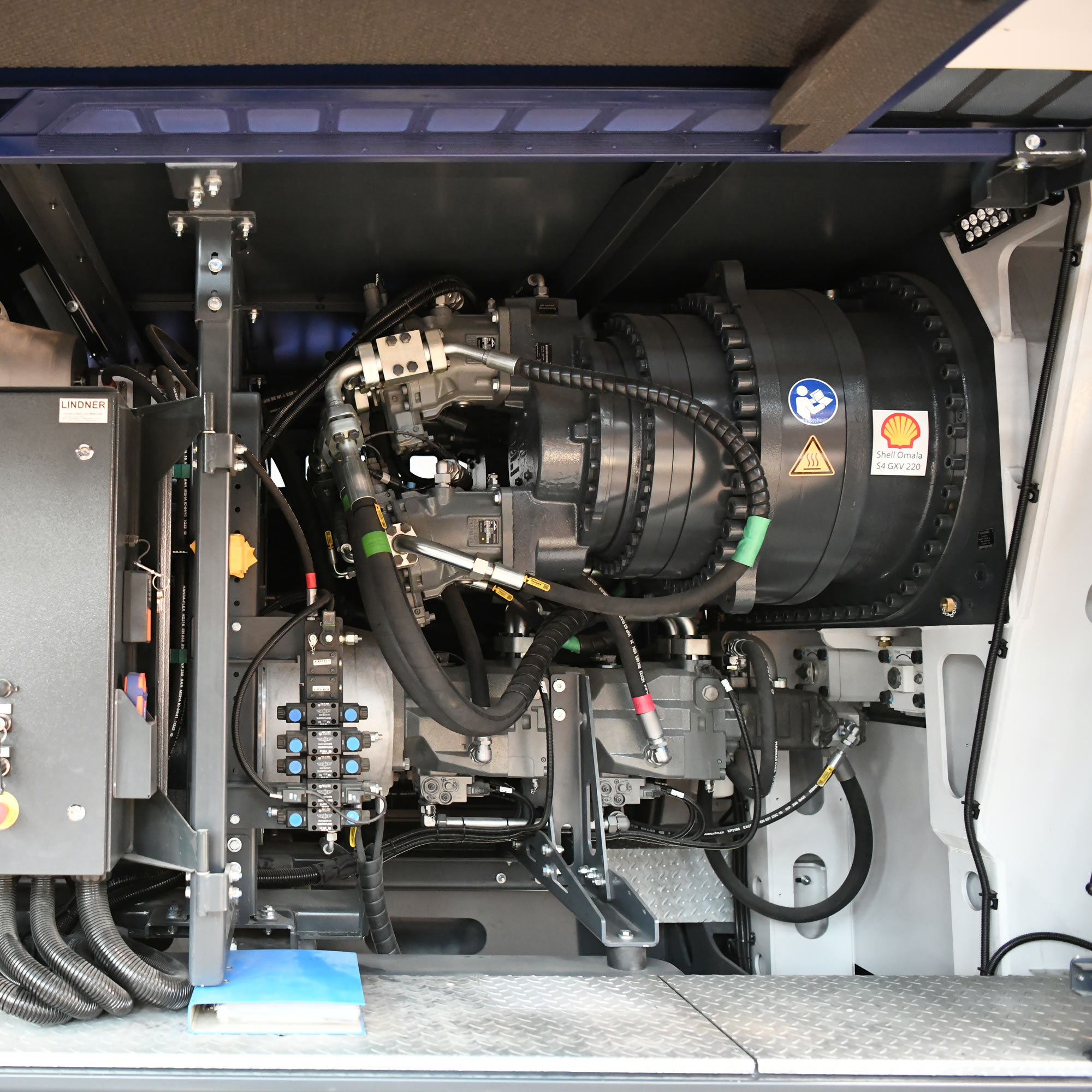

2 | Highly efficient electro-hydrostatic drive with torque reserves

Electro-hydrostatic drive for:

- High torque

- High effectiveness

- Quick change of shaft direction

- High energy efficiency

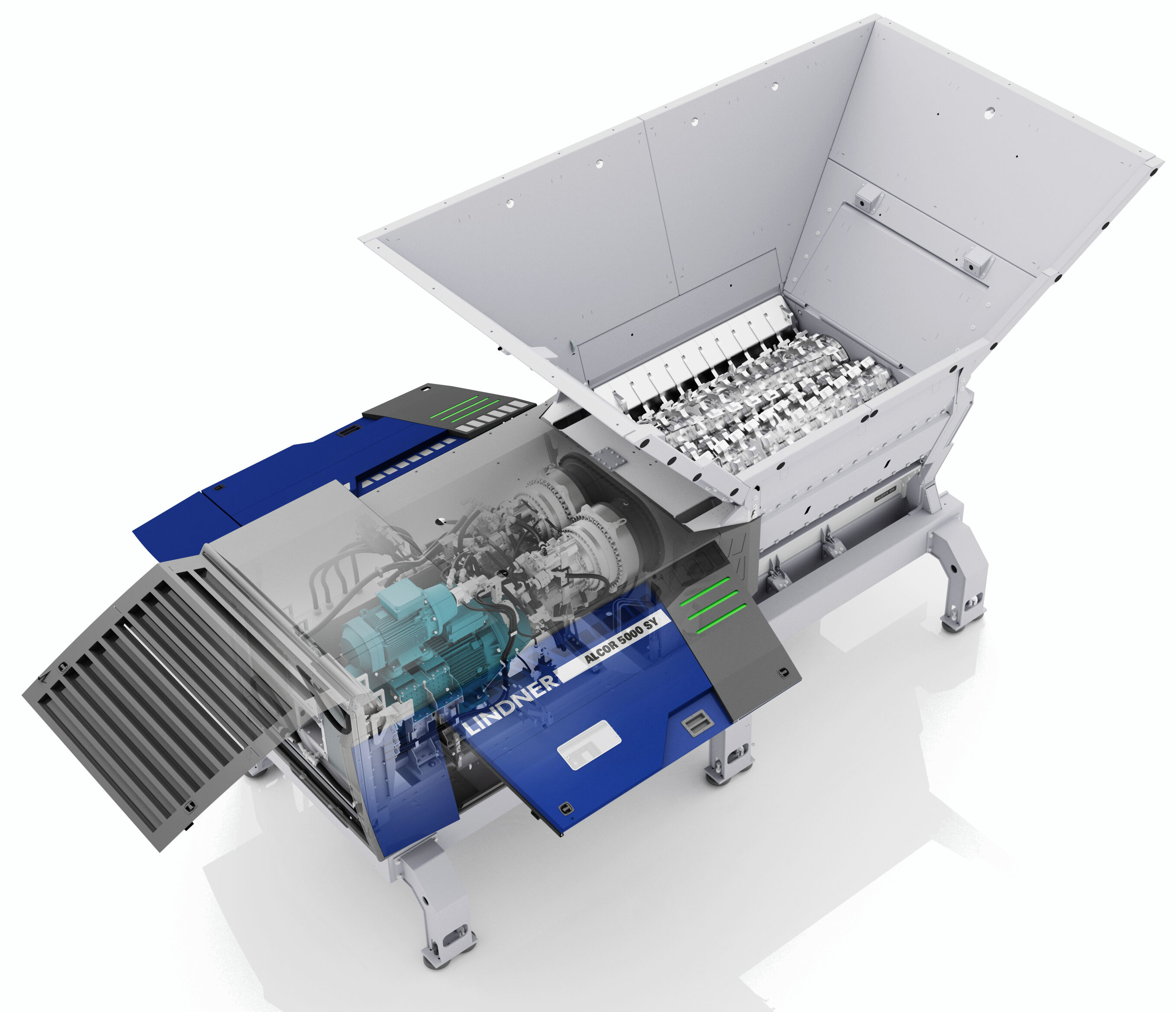

4 | Twin-shaft cutting system

The cutting system of the Alcore consists of two synchronously running, fully welded rotors. The synchronous ripping (ripping apart, ripping up) at low speeds with high torque combined with the dynamic energy recovery enables:

- Synchronous twin-shaft cutting system

- Two shaft types: SF (fine) and SR (rough)

- Perfect for waste wood, C&I, MSW, metal scrap

Fire prevention

THAT’S HOW TO PLAY IT SAFE

Lindner’s modern out-of-the-box FPS solution automatically detects and cools over heated particles in the material stream directly on the discharge conveyor, effectively preventing possible sources of fire. The system adapts the cooling process to the hazardous situation to ensure the facility operates optimally at all times.

- Precise detection of overheated materials

- Comprehensive monitoring of the entire cooling section

- Cooling process adapted to the hazardous situation

- Independent cleaning of the infrared sensors

- Temperature resistant and robust thanks to a special insulation system

- Highly flexible modular design

Watch video here!

Water sprinkling system

- To remove dust from the filling area

- 4 spray nozzles positioned in the enclosed hopper

- Switch it ON/OFF using the control panel

- Machine piping incl. central water supply

- Incl. heating system & piping insulation

FE metal separator

- Permanent over-belt magnet for ferrous metal separation

- Fitted above the conveyor belt

- Hydraulically height-adjustable

- Incl. discharge chute

Hardfacing kit

ADDITIONAL WEAR PROTECTION PACKAGE CUTTING SYSTEM

- Ideal for shredding particularly abrasive material

- Knife hardfacing

- Scraper hardfacing

Fire extinguishing system

- For effective fire extinguishing in the engine compartment

- Releases cooling and suffocating foam

- Self-monitoring, no electricity needed

- Robust and maintenance-free thanks to galvanised, non-pressurized pipes

Find your ideal solution and

Connect with us

INPUT & OUTPUT MATERIALS

Waste Wood

C&I | MSW

Light Scrap

MSW Plastics

KEY FEATURES