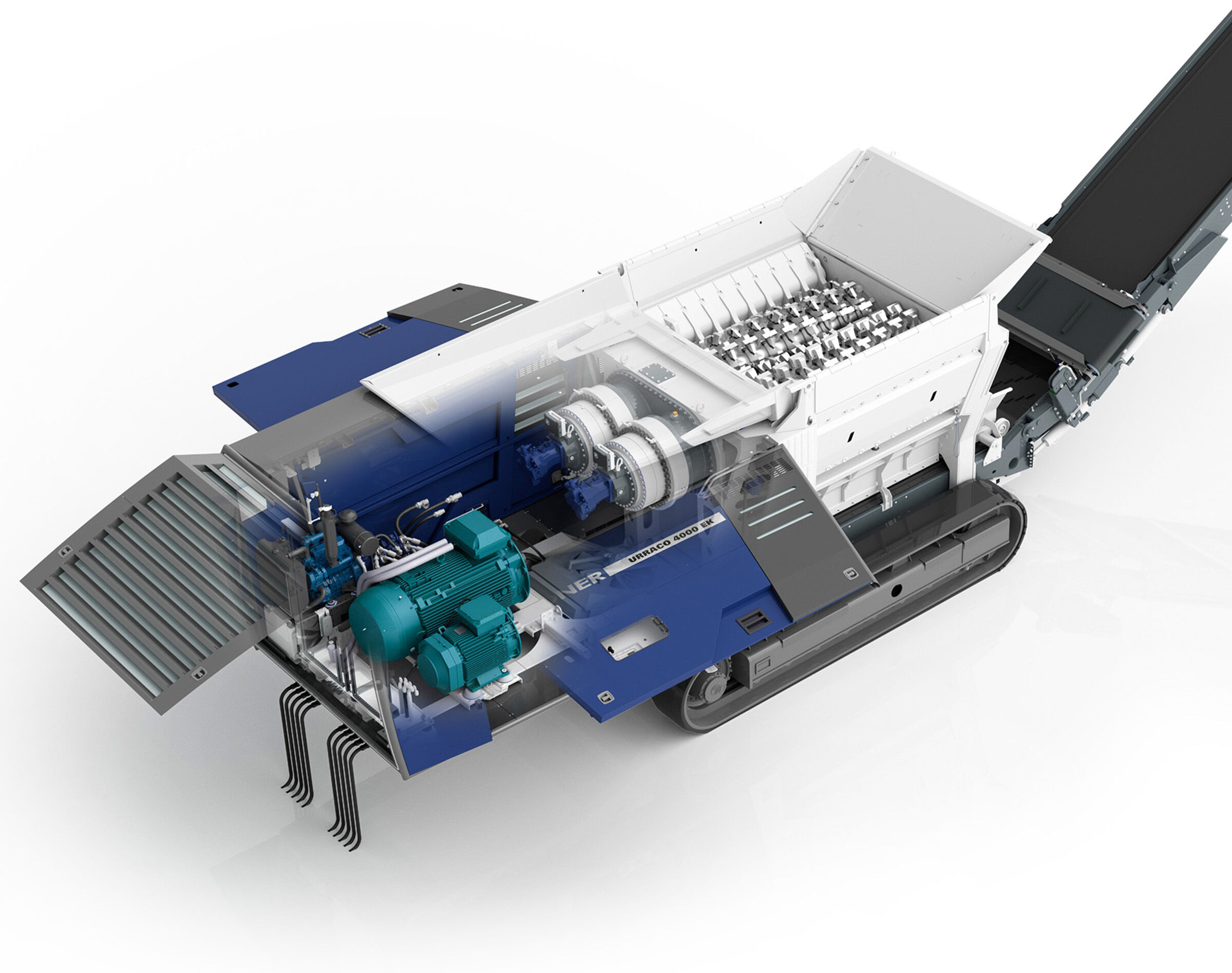

The Urraco 4000 models tick all the boxes:

Tried-and-tested quality paired with continuously high output.

1 | Twin-shaft cutting system

Our Urraco 4000’s slow-speed twin-shaft cutting system ensures aggressive intake and guarantees highly efficient shredding. Depending on the shaft selected, even the toughest materials such as railway sleepers and light scrap metal can be processed safely and effectively.

- INCREDIBLY PRODUCTIVE thanks to aggressive intake and synchronously running shafts

- ADAPTS PERFECTLY TO THE MATERIAL thanks to shaft pairs available in different designs

- MAXIMUM RESISTANCE with our fully welded cutters, rippers, scrapers and breaker bar

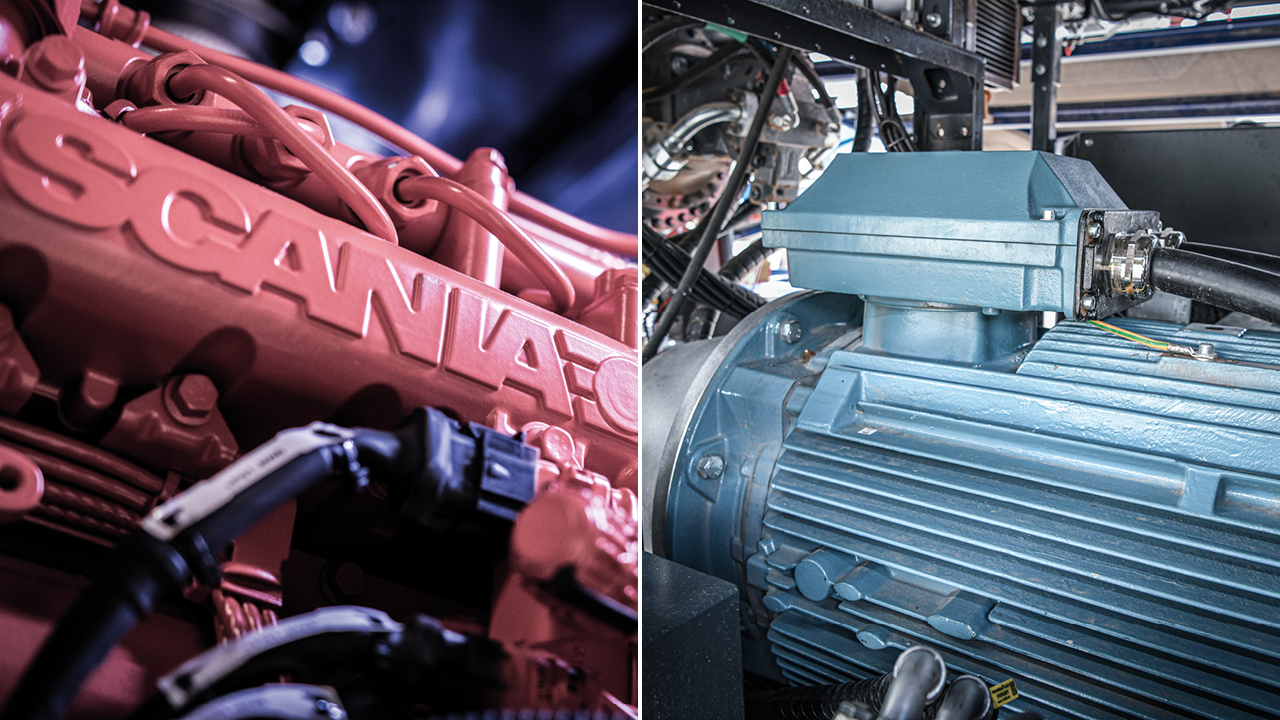

2 | Power Unit

POWERFUL DIESEL OR HIHG-PERFORMANCE ELECTRIC DRIVE

The Urraco is powered by an environmentally friendly, state-of-the-art diesel engine from Scania with the lowest emission standards (EU Stage V / US Tier 4f / EU Stage IIIA). The 3-circuit cooling system is working in unison with the engine and hydraulics ensures perfect air supply and cooling:

POWERFUL DIESEL ENGINE:

- High uptimes with our tried-and-tested SCANIA technology

- Environmentally friendly operation thanks to particulate filter and SCR exhaust cleaning system

- Low operation costs with our state-of-the-art engine technology

HIGH-PERFORMANCE ELECTRIC DRIVE:

- Highly efficient thanks to our tried-and-tested ABB electric motors

- Space-saving installation with no time-consuming cabling thanks to our integrated control cabinet

- Easy operation on more than one site with an optional plug&play connector

3 | Mobile hydraulics

THE HYDROSTATIC DRIVE SPORTS SELF-REGULATING HYDRAULICS WITH A MAXIMUM TORQUE OF UP TO 240,000 NM, CRUSHING MATERIAL POWERFULLY WITH ITS TWO SHAFTS.

- Maximum efficiency at the perfect operating point with our electronic BODAS control system

- Up to 15% more throughput compared to standard hydraulic systems thanks to faster adaptation to current performance requirements

- Adapts perfectly to input material thanks to pre-configured programs

4 | Independent power unit (E-models)

The E-models' independent power unit is particularly impressive since it makes it possible for the shredder to move easily to its next destination without any cables.

5 | Lindner’s Sky Flap

The Lindner Skyflap, an Urraco4000 product innovation, is completely removable and allows easy access to the complete cutting room length. The breaker bar can be easily accessed and removed easily with a forklift, enabling fast exchange of the cutting unit. This Lindner Skyflap also allows for quick cleaning of the cutting unit and easy removal of non-shreddables.

6 | Material Output & FE Metal Separator

WELL-ENGINEERED FEED AND DISCHARGE SYSTEMS

The integrated single-belt discharge conveyor is powered hydraulically and might be completely folded away. The height of the conveyor belt can be easily adjusted during operation by simply lifting the belt from the wheel loader during shredding. For particularly heavy materials such as light scrap and tough commercial waste, the conveyor belt can be reinforced with steel.

- FERROUS METAL SEPARATION with an optional integrated over-belt magnet

- CONSISTENT OUTPUT with our smart double tilting hopper system

- LOW DUST EMISSIONS due to the hydraulic height-adjustable conveyor belt, which can even be adjusted during operation

7 | Mobility

Depending on the degree of mobility needed, the Urraco 4000 models are available in various chassis versions.

E-models: base frame, or tracked chassis with independent power unit

Diesel models: base frame, tracked chassis or semi-trailer

8 | Maintenance door

The Urraco 4000s maintenance door enables even better access to the engine room.

9 | Powerlock quick connectors (E-models)

The Urraco 4000 E-models come with easy to use powerlock quick connectors.

FE metal separator

- Permanent over-belt magnet for ferrous metal separation

- Fitted above the conveyor belt

- Hydraulically height-adjustable

- Incl. discharge chute

Water sprinkling system

- To remove dust from the filling and discharge areas

- 4 pcs. spray nozzles positioned in the suction hood

- 2 pcs. spray nozzles positioned in the output area

- Incl. water filter and pressure limiter

- Switch it ON/OFF using the control panel

Fire extinguishing system

- For effective fire extinguishing in the engine compartment

- Releases cooling and suffocating foam

- Self-monitoring, no electricity needed

- Robust and maintenance-free thanks to galvanised, non-pressurized pipes

Hardfacing Kit

- Ideal for shredding particularly abrasive material

- Knife hardfacing (type HW)

- Scraper hardfacing (type HW)

- Support wire made of cobalt hard alloy

Find your ideal solution and

Connect with us

INPUT & OUTPUT MATERIALS

Waste Wood

C&I | MSW

Light Scrap

Green Waste