Nothing gets left to chance:

Effective technology in compact design.

1 | Skylight maintenance door

Cutting system access, Lindner style – quick, comfortable and 100% safe.

- EASY MAINTENANCE ACCESS thanks to the wide-opening maintenance door design

- 100% SAFE OPERATION with the mechanical safety lock and the pusher's special parking position

- QUICK CUTTING-UNIT ACCESS despite its compact design

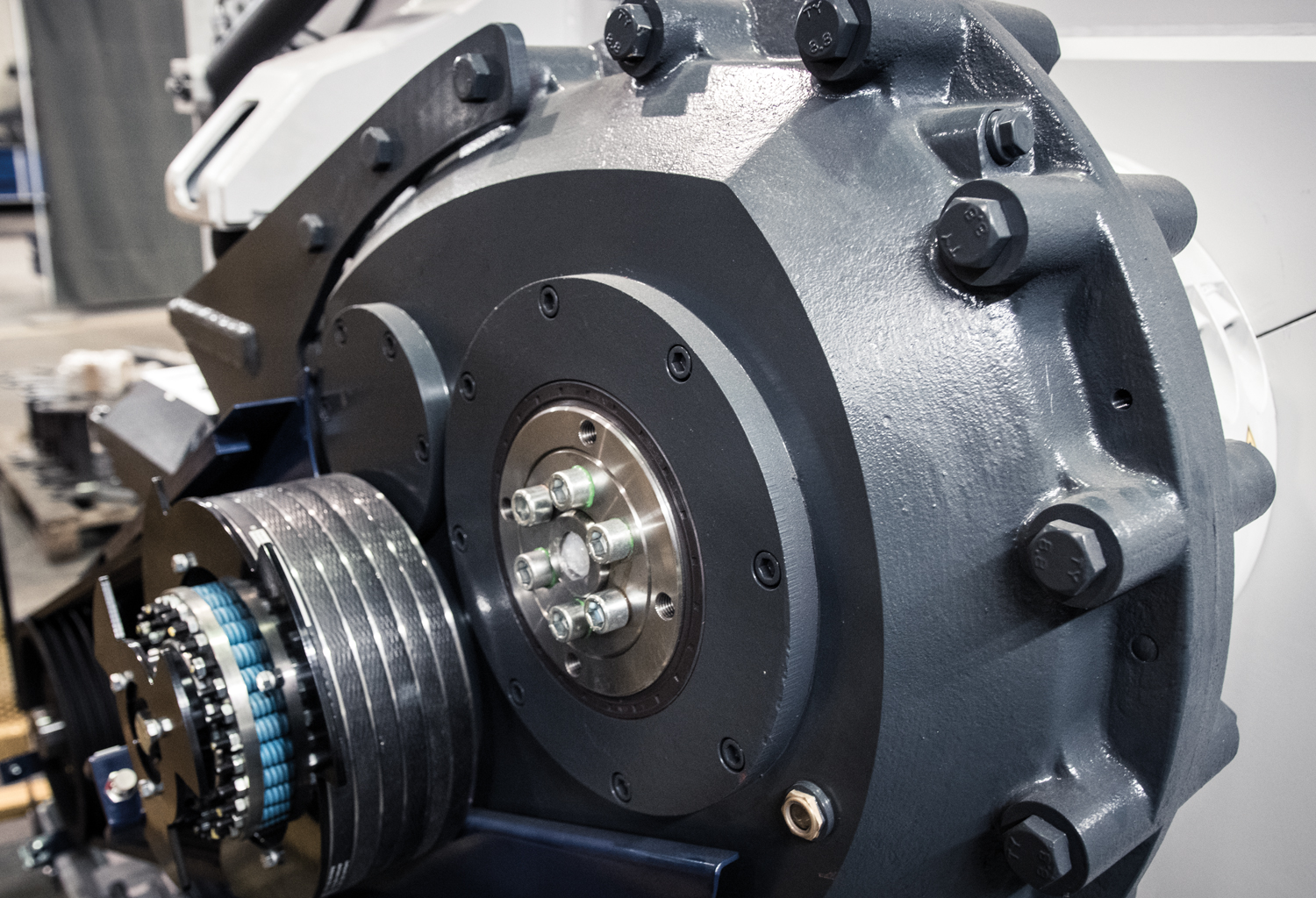

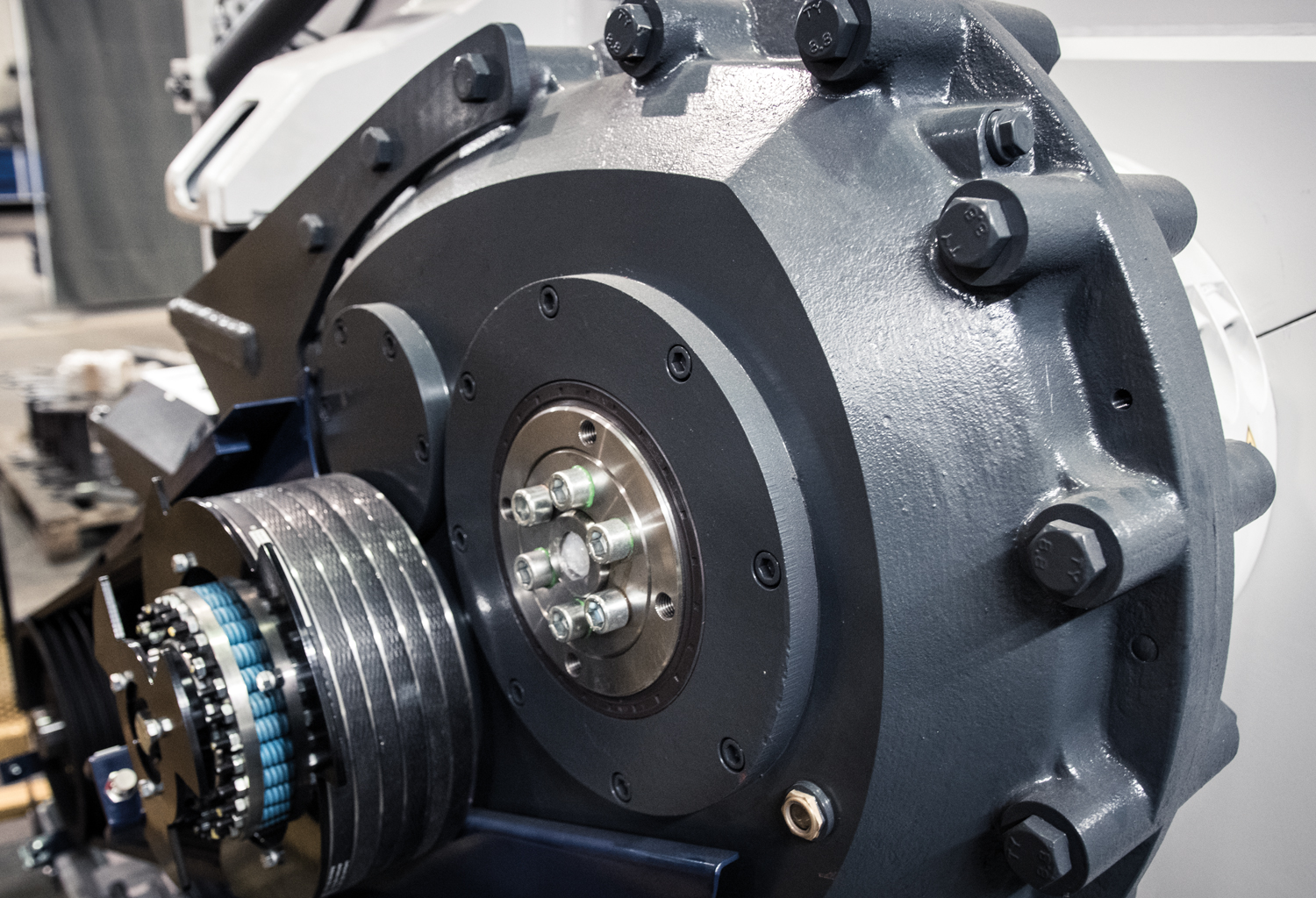

2 | Heavy duty gearbox drive

- POWERFUL SHREDDING due to powerful motors with high torque

- INDIVIDUAL ADAPTION to the material through variable speeds

- WORLDWIDE AVAILABILITYof the easy-to-change standard components

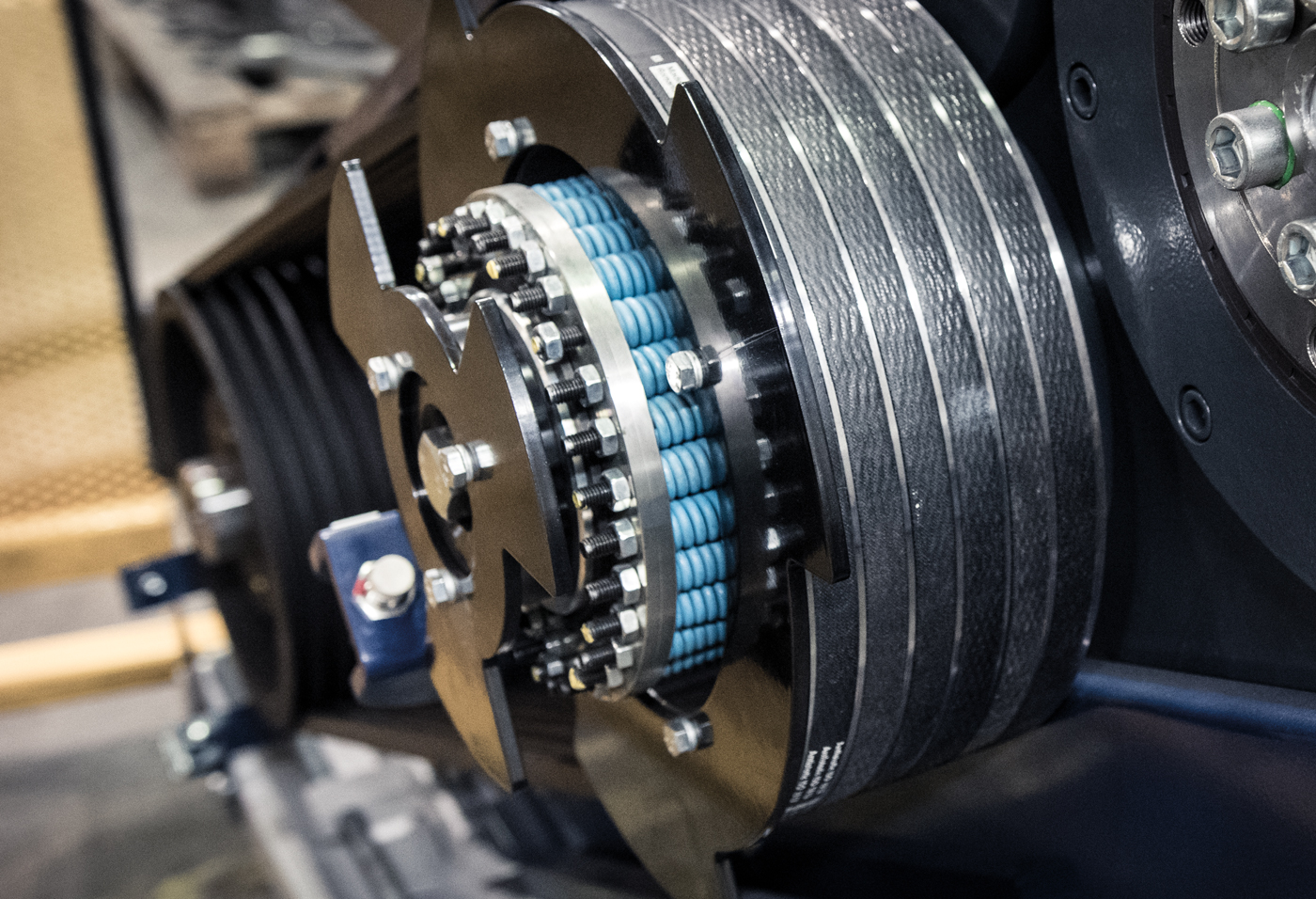

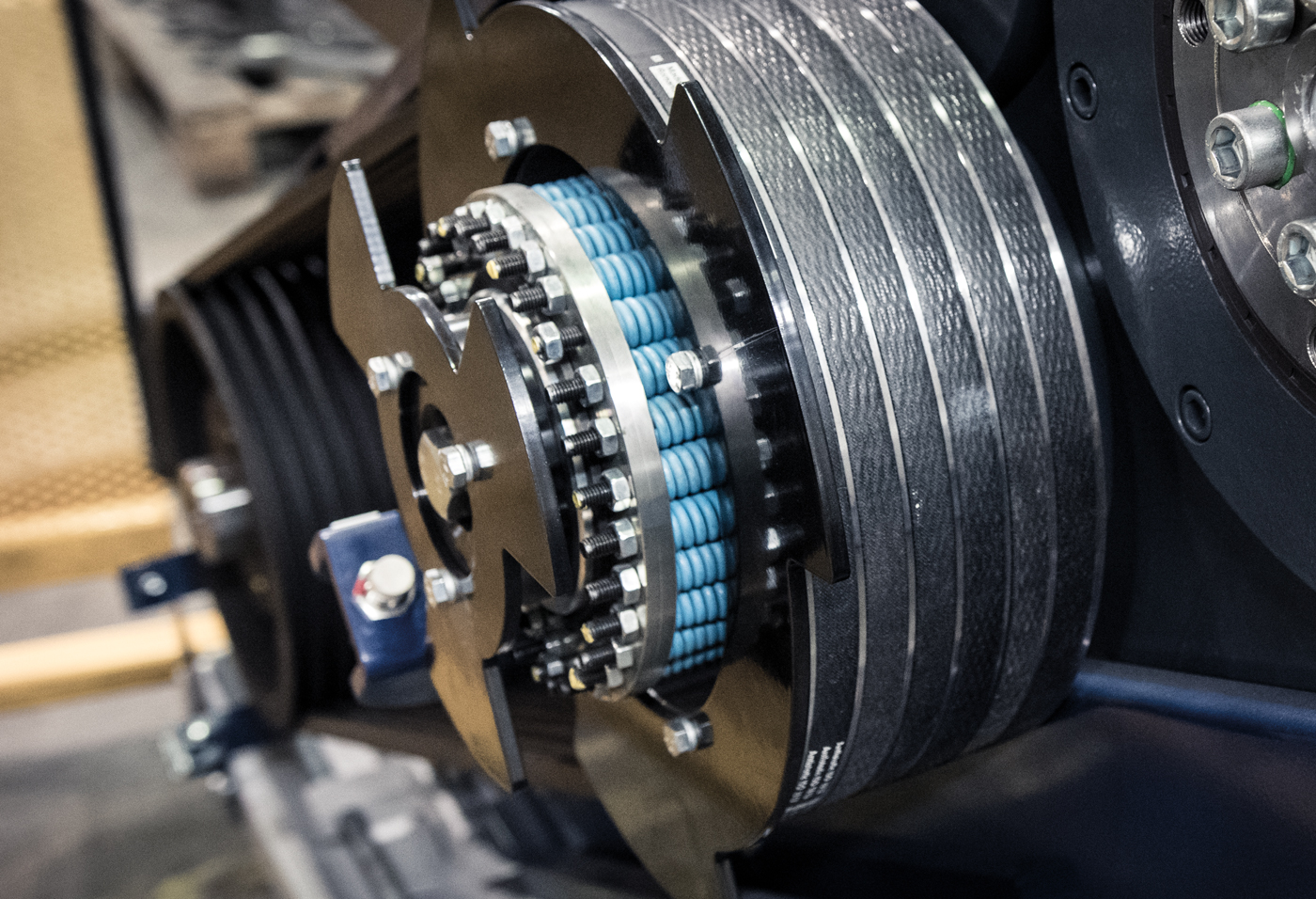

3 | Optional safety clutch

The torque-limiting clutch protects against damage to the drive unit when blockages are caused by foreign objects. Furthermore, the highly precise sensors facilitate the controlled powering down of the machine to preserve all components.

- PERFECT DRIVE PROTECTION thanks to the drive unit’s lightning-speed disengagement

- SECURE POWER DOWN with robust sensors

- FULLY ADJUSTABLE to various materials

4 | Internal pusher

Lindner's original: tried and tested a thousand times over, our internal pusher allows for easy and secure machine feeding. Our years of experience and continuous development have left their mark on its distinctive design.

- CONTINUOUS SHREDDIONG due to smooth feeding

- EASY FEEDING with a completely internal construction

- MAINTENANCE-FREE thanks to the absence of guide elements

- NO JAMMING as a result of additional comb and sealing bars

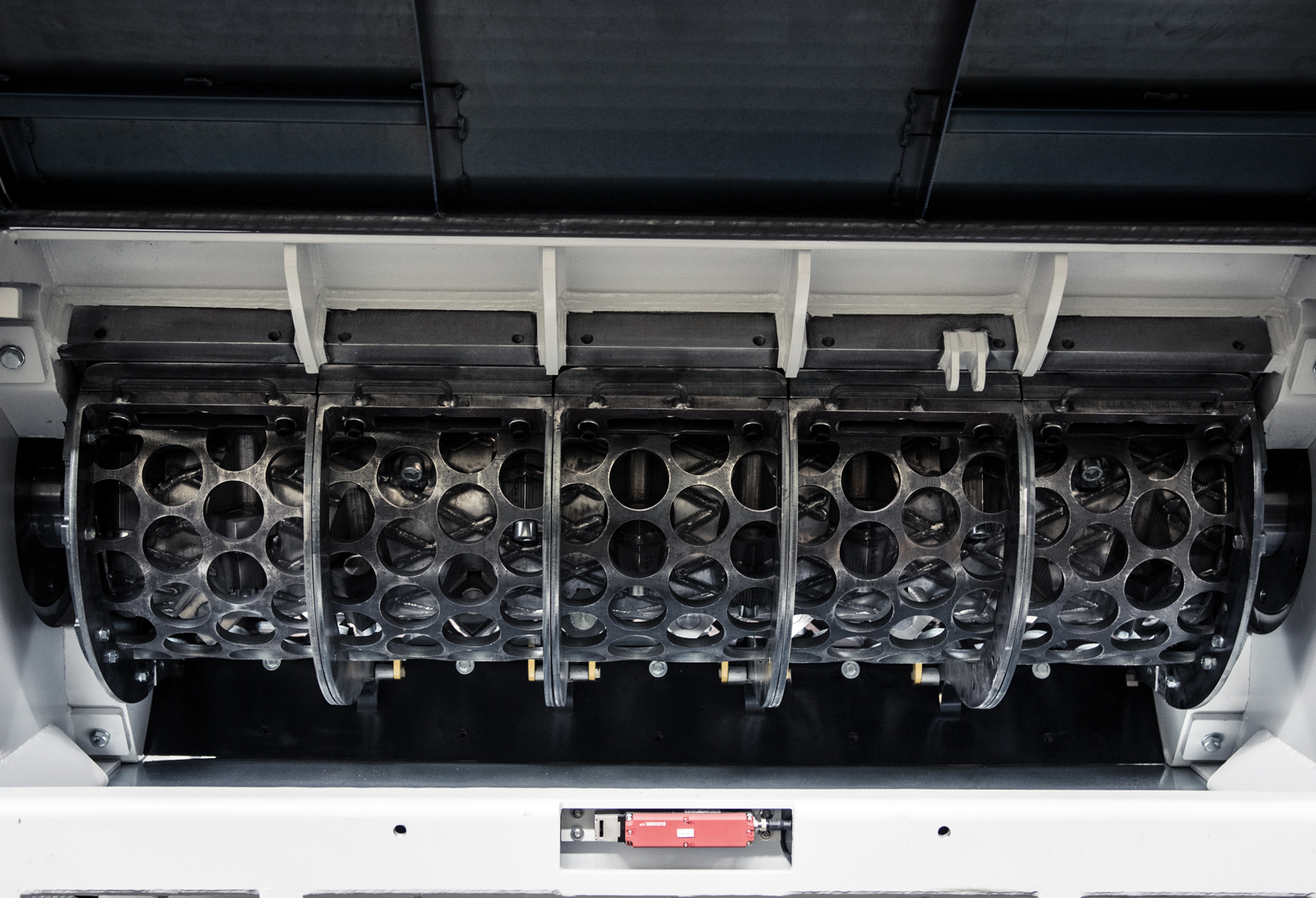

5 | Cutting system

The Antares’ individually configurable cutting system with pointed knives ensures maximum output while taking up minimum floor space. The cutting system is designed with various applications in mind, ensuring efficient shredding of a wide range of materials.

- OPTIMUM OUTPUT thanks to knife configurations that can be individually adapted to the requirement

- LOW WEAR AND TEAR thanks to the optional hardfacing of rotor and knife holders

- CONSISTENT PARTICLE SIZE with a cutting gap that is adjustable

6 | Plug & go screen unit

The swivel-mounted screen unit allows for easy and comfortable access for maintenance and refitting. The screens are available with various mesh widths and can easily be changed by hand by just one person – so you can quickly customise the shredder to the particle size you need.

- EASY ACCESS FOR MAINTENANCE AND FITTING thanks to the swivel-mounted, hydraulically operated design

- FLEXIBLE OUTPUT SIZES made possible with our screen units in various hole sizes

- EXTREMELY SAFE OPERATION with the electromagnetically locked screen access point, preventing access to the cutting chamber while the machine is in operation

Fire prevention

THAT’S HOW TO PLAY IT SAFE

Lindner’s modern out-of-the-box FPS solution automatically detects and cools over heated particles in the material stream directly on the discharge conveyor, effectively preventing possible sources of fire. The system adapts the cooling process to the hazardous situation to ensure the facility operates optimally at all times.

- Precise detection of overheated materials

- Comprehensive monitoring of the entire cooling section

- Cooling process adapted to the hazardous situation

- Independent cleaning of the infrared sensors

- Temperature resistant and robust thanks to a special insulation system

- Highly flexible modular design

Watch video here!

Water sprinkling system

- To remove dust from the filling area

- 4 spray nozzles positioned in the enclosed hopper

- Switch it ON/OFF using the control panel

- Machine piping incl. central water supply

- Incl. heating system & piping insulation

Rotor cooling

Complete rotor cooling system

- Ideal for shredding temperature-sensitive materials

- Prevents clumping and melting of the final product

- Incl. cooling aggregate

- Water connection pipe: 1"

Find your ideal solution and

Connect with us

INPUT & OUTPUT MATERIALS

FILM

HDPE Plastics

Paper

CONFIDENTIAL DATA

KEY FEATURES

LINDNER ADVANTAGES