post consumer plastics recycling

WHEN ONLY THE BEST WILL DO.

Lindner’s multi-stage processing facility for post-consumer plastic is in a class of its own. Perfectly matched components guarantee high output quality. Robust high-end shredding, washing and drying components ensure smooth 24/7 operation with low maintenance and consistently high throughput. It has never been so easy to guarantee the ideal input for subsequent processes.

Shredder requirements

For this application, the shredder must be particularly resistant to foreign matter. Due to the high amount of abrasive materials such as soil, sand and other impurities, the machine must have specific features. The aim of shredding is to achieve a material flow that is as homogenous as possible to allow for subsequent processing. The MICROMAT series is especially well suited as a primary shredder for processing plastics thanks to the variety of construction options it comes in.

Related Product

Anforderung an den Shredder

Der Zerkleinerer muss dafür besonders robust und störstoffresistent ausgeführt sein, um die hohe Bandbreite an Inputmaterialien zu meistern. Das Ziel der Zerkleinerung ist eine wirtschaftliche Aufbereitung mit geringsten €/t-Kosten für den Betreiber mit einem stets konstanten Austrag von 50-100mm, fix und fertig verwendbar zur Befeuerung im Zementofen Kalzinator oder als Wirbelschicht- Brennstoff. Der POLARIS als die Kompaktlösung erfüllt die Anforderungen am besten.

Related Product

Anforderung an den Shredder

Der Zerkleinerer muss dafür besonders robust und störstoffresistent ausgeführt sein, um die hohe Bandbreite an Inputmaterialien zu meistern. Das Ziel der Zerkleinerung ist eine wirtschaftliche Aufbereitung mit geringsten €/t-Kosten für den Betreiber mit einem stets konstanten Austrag von 50-100mm, fix und fertig verwendbar zur Befeuerung im Zementofen Kalzinator oder als Wirbelschicht- Brennstoff. Der POLARIS als die Kompaktlösung erfüllt die Anforderungen am besten.

Related Product

Anforderung an den Shredder

Der Zerkleinerer muss dafür besonders robust und störstoffresistent ausgeführt sein, um die hohe Bandbreite an Inputmaterialien zu meistern. Das Ziel der Zerkleinerung ist eine wirtschaftliche Aufbereitung mit geringsten €/t-Kosten für den Betreiber mit einem stets konstanten Austrag von 50-100mm, fix und fertig verwendbar zur Befeuerung im Zementofen Kalzinator oder als Wirbelschicht- Brennstoff. Der POLARIS als die Kompaktlösung erfüllt die Anforderungen am besten.

Related Product

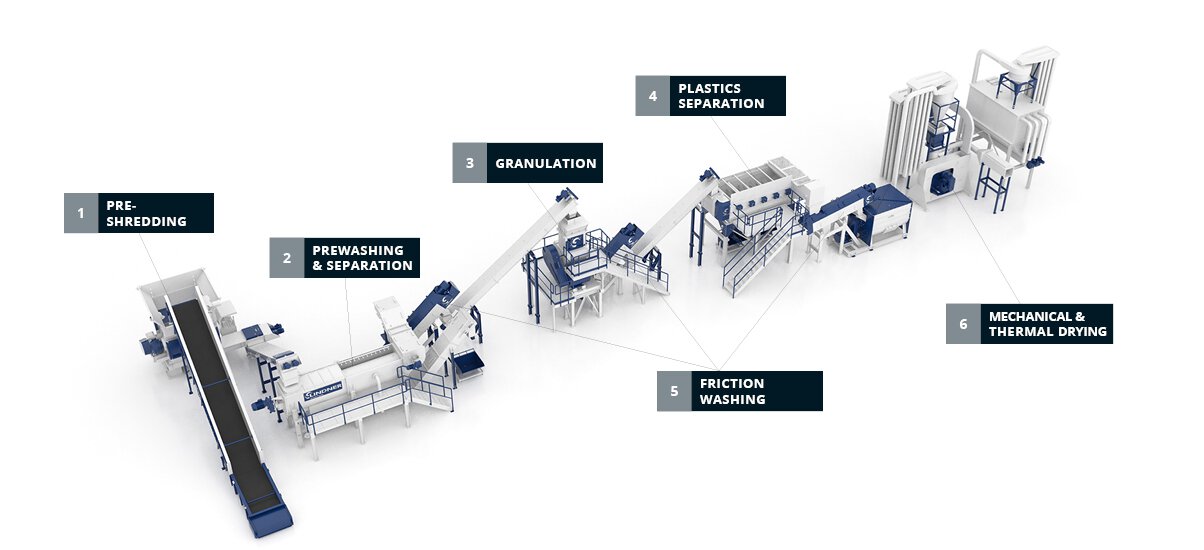

Shredding

Shredding is an essential step in a smooth-running process chain. Untreated plastic waste either in baled or loose form is fed into the machine with wheel loaders or a conveyor belt.

The output is consistent, the cut precise and 90% of the output will be smaller than 60 mm with an output of up to 5 metric tons per hour.

PREWASHING

The requirements for prewashing are clearly defined. Pre-shredded plastics are often heavily contaminated and loaded with foreign matter. The rafter’s well-engineered technology effectively separates abrasive matter and prepares the material for all following processes.

GRANULATION

Now free from foreign matter, the material is granulated using a wet granulator that screens the material to the preferred particle size to make recycling particularly efficient.

PLASTICS SEPARATION

Categorising plastics according to their specific weight. This step is executed with Lindner Washtech’s gravitator, a machine that combines state-of-the-art features with the tried-and-tested sink-float method. In this process, not only is it important that the output material is homogeneous, but the machine’s construction must also be compact and efficient.

FRICTION WASHING

Efficient washing through friction. The Lindner Washtech friction washers clean even the smallest particles very effectively. The machine size can be adjusted to the customer’s specific throughput requirements, achieving rates of up to 4 metric tons per hour. The machine’s screens and paddles are also customisable. The Hot-Wash can be added-in additionally for extremely tough contaminants. More Info

DRYING

The shredded and washed material is fed into a centrifuge where the plastic flakes are dried in controlled conditions. The resulting centrifugal forces contribute to cleaning and drying the materials. Finally, the material is thermally dried and can subsequently be transferred for extrusion.

CIRCULAR ECONOMY - PLASTICS AS A RAW MATERIAL

Processing plastics waste for a resource-saving plastic life cycle concept

ZERO WASTE POTENTIAL

Lindner’s plastic recycling solutions are all the rage: thanks to an ever-increasing demand for polymers and the worldwide desire to use valuable resources more efficiently, higher-quality recyclates are highly sought after. The key to meeting these quality requirements is to prepare the material to be recycled as well as humanly possible.

POST-CONSUMER PLASTICS RECYCLING

Post-consumer waste is created by consumers, e.g. individuals and households. The field of post-consumer plastics in particular demands high machine standards since the material might not only contain abrasive matter but also food scraps. The foreign object-resistant shredder and the high-end washing technology ensure a homogeneous product ready for extrusion. Manufacturing companies can then turn the resulting lenticular plastic raw materials into the final product. Waste is transformed into a new product, saving energy and resources.